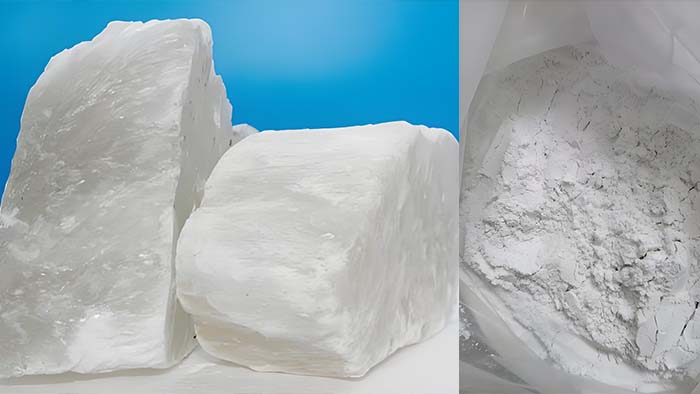

Gypsum is indispensable in both industrial and construction applications. To turn raw gypsum into ultra-fine, high-grade powder, Clirik’s HGM series ring-roller micronizer is often the preferred solution. Below is a concise walkthrough of the complete workflow.

Oversized gypsum lumps are first broken down in a hammer or jaw crusher until the fragments measure roughly 10–30 mm.

A bucket elevator lifts the crushed fragments to a storage hopper. From there, a vibrating feeder doses the material evenly into the mill’s grinding chamber via an inclined feed pipe.

Inside the chamber, a motor-reducer assembly drives the main shaft and rotating table. Dozens of grinding rollers, guided by the table’s roller pins, revolve within a stationary grinding ring. Gypsum particles are flung outward by centrifugal force, caught between rollers and ring, and progressively pulverized through multiple compression and shear events.

A high-pressure fan draws ambient air through the system, carrying the milled gypsum upward into an integrated classifier. Coarse particles rejected by the classifier’s spinning impeller fall back for additional grinding, while fines meeting the target specification continue with the airflow.

Acceptable powder is separated from the air stream in a cyclone collector and discharged through a rotary valve as finished product. Trace dust entrained in the exhaust air is trapped by a pulse-jet bag filter. Periodic reverse-pulse cleaning dislodges the dust, which is then conveyed to the packaging line.

The entire circuit operates under a closed-loop, balanced-pressure design. The pulse-jet collector keeps workplace emissions well below regulatory limits, ensuring a clean production environment.

The HGM mill handles non-flammable, non-explosive materials up to Mohs 6 hardness. Finished fineness is adjustable from 325 to 3 000 mesh, and capacity ranges from 0.4 t/h to 45 t/h, making it a versatile choice for ultra-fine powder production.

上一篇: Grinding Calcium Carbonate with HGM Ultrafine Grinding Mill

下一篇: Grind 1000mesh Limestone Powder with CLIRIK HGM Grinding Mill

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved