Kaolin clay tailings production aerated concrete raw material grinding equipment

2021-07-02 02:50:18

Research on the production of aerated concrete using kaolinite tailings has already appeared in China. Some institutions have studied the fineness of kaolinite tailings and the sieve margin to the hardness of aerated concrete, including the addition of 200 mesh fineness kaolinite tailings and other concrete raw materials. The smaller the screen residue, the longer the grinding time and the stronger the hardness of the aerated concrete, but there is a time peak, not the longer the better.

Shanghai Clirik Machinery Co., Ltd. provides customers with highly configurable kaolin tailings milling machinery in response to the high throughput requirements of kaolin tailings. It can meet the requirements of concrete manufacturers.

1. The cause of kaolin tailings and its impact on the environment

Kaolin tailings are solid wastes discharged from kaolin mines after beneficiation. For a long time, many units have only devoted to the mining and processing of kaolin mines, and there are few studies on the recycling of kaolin tailings. Most of them are piled up in the open air, or used for paving roads, returning fields and tamping foundations. Continuous accumulation, occupying a large amount of land, polluting water quality, and causing vegetation damage and soil erosion, and even causing mudslides, seriously affecting the ecological environment, but also caused excessive consumption of non-renewable resources such as kaolin. Therefore, it is particularly important to comprehensively utilize kaolin tailings, recycle them, turn waste into treasure, protect the environment, and benefit society and future generations.

2. The influence of kaolin tailings fineness and grinding time on the strength of aerated concrete

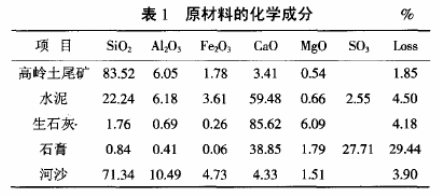

First, let's take a look at the configuration table of raw materials used to produce aerated concrete from kaolin tailings (Table 1). It can be seen from the table that an institution using kaolinite tailings to develop aerated concrete originally included kaolinite tailings, cement, quicklime, gypsum, and river sand. The fineness of kaolinite tailings is 200 mesh.

Figure 1: Composition list of aerated concrete raw materials kaolin tailings and other raw materials

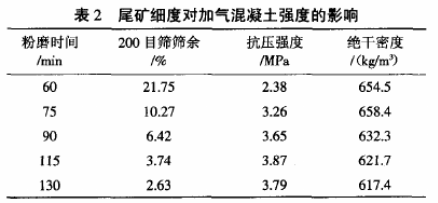

Figure 2: Effect of kaolinite tailings fineness on aerated concrete hardness

Then, we look at the effect of kaolinite tailings fineness on the strength of aerated concrete. It can be seen from Table 2 that the compressive strength of aerated concrete products increases as the fineness of kaolin tailings increases. Norifumi Isu et al. proposed that the increase in fineness of tailings can accelerate the formation of tobermorite. When the tailings were ground for 115 min, the enhancement effect was the best. As the grinding time is further extended, the strength of the product has decreased to a certain extent, presumably because the fineness of the tailings is too small, and the unreacted residual cores in the product are too small, and a good skeleton structure cannot be formed inside the product ), which affects the strength of the product; at the same time increases the water demand of the product and increases the shrinkage of the product. Considering the economic and performance factors, it is more appropriate to select the grinding time of kaolin tailings at 115min.

3. Selection of kaolin tailings and aerated concrete grinding equipment

From the above analysis, it can be seen that the use of kaolin tailings to produce aerated concrete, raw material fineness, grinding time have a previous decision on the hardness of aerated concrete. The choice of kaolin tailings milling machine and aerated concrete raw material mixing milling machine is an important equipment for raw material milling efficiency and fineness.

The slag vertical mill can process all kinds of mining tailings, slag, blast furnace slag and industrial solid waste, and it is also handy for kaolin tailings with low hardness. The slag vertical mill is used to process kaolin tailings to produce 200 mesh fine powder, which can reach a processing capacity of 23 to 220 tons per unit.