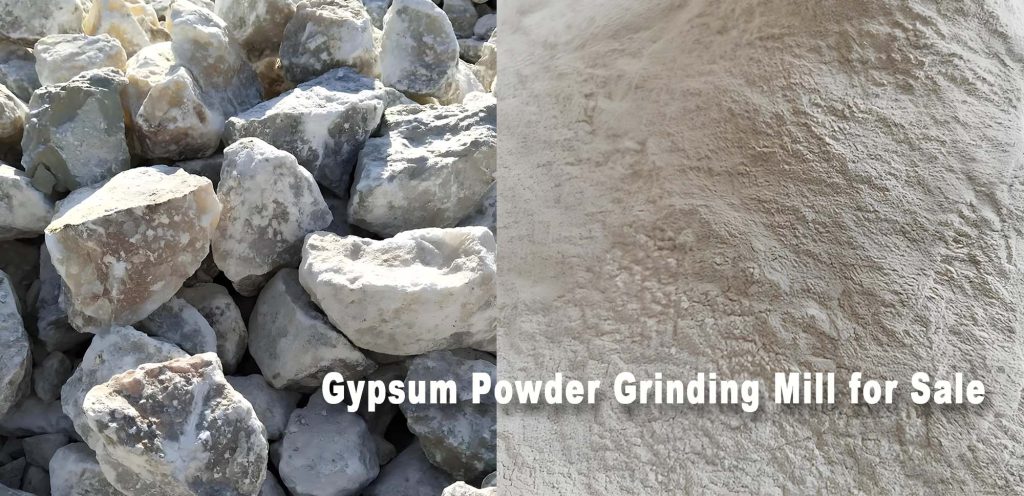

In a significant development for the gypsum processing industry, Clirik's HGM Grinder has successfully achieved the production of gypsum powder with a fineness of up to 3000 mesh. This achievement sets a new benchmark for ultra-fine grinding and highlights the advanced capabilities of Clirik's HGM series.

Clirik's HGM Grinding Mill is a state-of-the-art ultra-fine grinding solution designed to handle a wide range of materials, including gypsum. It is renowned for its high efficiency, precision, and reliability, making it an ideal choice for industries requiring ultra-fine powders.

The HGM Grinding Mill operates on a sophisticated mechanism that ensures the highest level of grinding efficiency and precision. The main components of the mill include a grinding host, classifier, powder collector, dust cleaner, and a high-pressure blower. Here is a detailed breakdown of how the mill works:

Material Preparation and Feeding: Large gypsum blocks are first crushed into smaller particles by a hammer crusher. These particles are then transported to a storage hopper and fed into the grinding chamber through a vibrating feeder and inclined feed pipe.

Grinding Process: When the mill is in operation, the main shaft driven by an electric motor rotates the grinding ring and rollers. The material is driven to the edge of the turntable by centrifugal force and falls into the grinding chambers. Here, the material is subjected to repeated impacts, rolling, and grinding by the rollers.

Classification and Collection: The high-pressure air blower continuously inhales air within the grinding mill, and the airflow carries the ground material to the classifier. The classifier's high-speed impeller separates the material based on particle size. Coarser particles are returned to the grinding chamber for further processing, while fine powder is carried by the airflow into the cyclone powder collector. Most of the qualified powders fall and exit from the discharging valve at the bottom.

Dust Control: A small proportion of fine powders, along with the airflow, moves to the dust cleaner and clings to the surface of the filter bags. The fine powders clinging to the surface fall down by the sudden vibration of the filter bags, caused by the instantly ejected high-pressure gas controlled by the pulse valve. The filtered clean air is emitted from the air outlet of the muffler.

The HGM Grinder offers several key advantages that make it a superior choice for gypsum processing:

Clirik's HGM Grinding Mill has proven to be a game-changer in the gypsum processing industry. Its ability to produce ultra-fine powder with high efficiency and precision makes it an indispensable tool for modern industrial applications. Whether you are looking to improve the quality of your gypsum products or increase production capacity, the HGM Grinding Mill is the perfect solution.

For more information on how Clirik's HGM Grinding Mill can benefit your business, or to discuss your specific requirements, please contact Clirik Machinery. Our team of experts is ready to provide detailed information and support to help you take your operations to the next level.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai Clirik Machinery Co., Ltd.All rights reserved