40 Years history production base and exporter

Pre-sale service

Pre-sale service

24 hours online

Free technical support and solutions

Factory visit anytime, free pick up

Sales service

Sales service

Commit to delivery fast

Provide On-site installation service

Free training of product operation

After-sales service

After-sales service

365 days after-sales online

Solve customer feedback problems timely.

Help customers optimize and upgrade equipment

Contact Us ( sales@clirik.com )

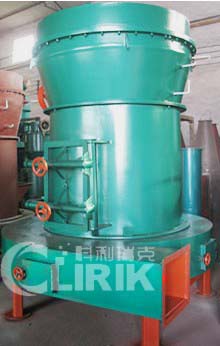

Necessary grinding equipment:

Raymond grinding equipment, water granulated slag vertical grinding euqipment, water granulated slag three-ring superfinegrinding equipment and HGM micro powdergrinding equipment. Grinding by Raymond grinding equipment, water granulated slag verticalgrinding equipment and water granulated slag three-ring super fine grinding equipment and HGM micro powdergrinding equipment, the finished powder can be reach 250meshs~ 3000meshs, it is a kind of high quality cement and concrete raw material.

Technical data of grinding equipment 1:

|

Model |

HGM80 |

HGM90 |

HGM100 |

HGM100A |

HGM125 |

|

Ring Diameter(mm) |

800 |

900 |

1000 |

1000 |

1250 |

|

Ring Number/PCS |

3 |

3-4 |

3-4 |

4 |

4 |

|

Roller Number/PCS |

21 |

24-32 |

27-36 |

27-36 |

40-44 |

|

Main Shaft Speed/r. p. min |

230-240 |

200-220 |

180-200 |

180-200 |

135-155 |

|

Input Size/mm |

≦15 |

||||

|

Finished Size/um |

5-47(325-3000) |

||||

|

Capacity t/h |

0.4-4.5 |

0.4-5.5 |

0.4-6.5 |

0.4-7.5 |

0.7-10 |

|

Outlet Size L*W*H/m |

13.9*4*6.2 |

14.7*4.8*7.2 |

18*4.6*8.6 |

18*4.6*8.6 |

14*9*10 |

Technical data of grinding equipment 2:

|

Type |

Roller |

Max. feeding size(mm) |

Fineness of product(mm) |

Output (t/h) |

Power of machine(KW) |

Overall Size(mm) |

||

|

No. |

Diameter (mm) |

Height(mm) |

||||||

|

YGM7815 |

3 |

260 |

150 |

15-20 |

0.025-0.005 |

0.28-3 |

18.5 |

4300*3500*5100 |

|

YGM8314 |

3 |

270 |

140 |

15-20 |

0.025-0.005 |

0.35-3.4 |

22 |

5300*4100*5200 |

|

YGM9517 |

4 |

310 |

170 |

15-25 |

0.025-0.005 |

1.5-6.5 |

37 |

7100*5900*7900 |

|

YGM4121 |

5 |

410 |

210 |

15-25 |

0.613-0.044 |

3-12 |

75 |

7850*8000*9700 |

Note: This specification is just referencing, any changes are subject to the products.

Should you have any questions, please do not hesitate to contact me.

Phone: 0086-21-20236178

Contact person: Cherry. Zhao

E-mail: info@clirik.com;clirik_grinder@126.com

Website: http://www.grinding-equip.com; http://www.mill-grinding.com; http://www.saico.net.

Through long-term arduous technology research and international communication, our product quality has been in line with international level, winning a world-wide acclaim and honor, and our products are exported to ninety countries and regions like Tanzania, Nigeria, South Africa, Kenya, Turkey, Saudi Arabia, Philippines, Indonesia, Malaysia, Vietnam, Mexico, Brazil, Russia, Uzbekistan, Australia, etc.

Please feel free to write down your requirement in the form below.

We will reply you within 24 hours.

Copyright: Shanghai CLirik Machinery Co., Ltd.All rights reserved